OPP hot glue label sticking machine

1. Name: hot glue opp label sticking machine

Model :JL-04 series

Label sticking method: round label sticking

Usage glue type: hot glue

1.1).label cutting knife adjust easy

1.2).vacuum absorb wheel adopt to high hardness material making, add shrink treatment programme to cut label abrasion, avoid statics produce.

1.3).exchange compatible workin can do at 10minute quickly finish.

1.4). Can use manual manipulation precision and convenient to adjust knife plate site.

1.5). Vacuum absorb wheel and label cutting part adopt to abrasion heat special matrial making.

1.6).when change label length, auto adjust button can auto adjust I-MARK position

2. Usage label

① label material:OPP(gear type)

②label specification: as client requirement

③ label sticking method: linear type hot glue sticking label

3. Facility description

3.1) adopt to wheel stick label method

3.2) via label roll transport label via label wheel supply,as guid rail to do label sticking operation.

3.3) label via label supply wheel, transit auto test I-MARK

3.4) once sure electrici eye position, modem auto adjust wheel supply operation speed, can no mistake cutting label position.

3.5) label via label supply gear, into cutting part to do cutting operation, then cutting label transport to vacuum absorb plate

3.6) via conveyor belt transport container to wheel gear to do arrange, after glue spray label, to do guid first time label sticking, then rely on in-phase operation to do perfect label sticking operation.

4. Device descripton:

4.1) controlling: operation controling,frequency convertor

4.2) safe device

① drive part set overload operation protection device

② supply wheel gear abnormal statics stop device

③ no bottle supply inspection device

④ bottle supply overload inspection device

5. Main fracture

5.1)conveyor

5.2) supply star wheel

5.3) label station

5.4) vacuum absorb plate

5.5) drive part

5.6)hot glue glue supply machine

5.7)glue roller wheel

5.8)in phase belt

5.9) label cutting part

5.10) label guid rectify

5.11)machine frame

5.12) vacuum system and air source treatment

5.13) controlling system

6. Compatible part

6.1) wheel gear and guard board

6.2) cavcuum absorb plate

6.3)screw pusher

6.4) rub bottle guard board

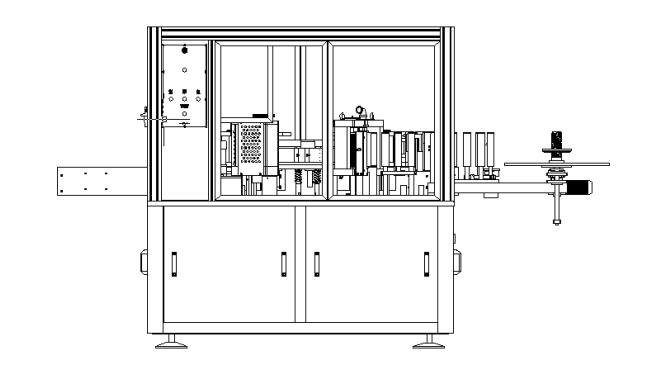

2. Machine chart

1. Label plate 2 pull and transit 3 cutting knife anf transit 4. Label correct rotate drum 5.glue spray roller

6.rub label fracture 7.thumble bottle wheel 8. Bottle entry screw 9. Main machine conveyor section. Machine frame

◆ Pull and transit-via motor pull roller, via screw thread compressor roller pull roller, label via comrpessor strength roller and pull roller middle cross, via controlling system servo motor rotate, reach pull and controlling label length aim.this fracture label supply steadily.◆ Cutting knife and transit-adopt to single knife fracture, via vaccum bump function,absorb viapull transit label, rotate to cutting knife to cut off, and have compressor air let label ,back assistant blow, then cutting knife smoothly transit to label sticking drum. Then fracture part strongly and enduration, cutting vibrate alittle noise,long small knife life.

label spray and hot glue machine-when working cylinder push label spray fracture let label spray roller and label rotate drum cutting and sticking, and same time glue machine let glue melt to requirement statics and temperature, constant pressure-evenly supply label spray fracture, glue spray roller, via glue roller method let glue evenly sitck at label two head,. This ftracture label spray evenly, save glue.

Facility main parameter

Facility name | Automatic linear hot glue opp label sticking machine |

Machine model | JL-04B-4P |

Main motor power | 2.2KW |

Main motor brand | Taiwan brand |

controller | Schneider |

Servo motor | Schneider 1.5KW |

PLC module | Schneider |

transit | SICK Schneider Panasonic |

programmer | SICK |

Low pressure electricity | Schneider |

Voltage | 380V±10% |

Frequency convertor | 50HZ |

Whole machine power | About 8KW |

Label type | Single round body label |

Applied bottle type | Round bottle ∮40-105mm,height=80-350MM |

Label size | Length 125-325mm,height 20-150mm |

Label spray method | Roller coating(label head and end end about each 10mm) |

Label usage method | Roll label |

Capacity | 12000b/h (common 500ml bottle type) |

|

|

Compressor air pressure | MIN5.0bar MAX8.0bar |

Compressor air consumption quantity | 0.2M³/minute |

Whole machine weight | About 2000kg |

Machine overall size | L=3150 W=1570 H=1800 |